1 / 3

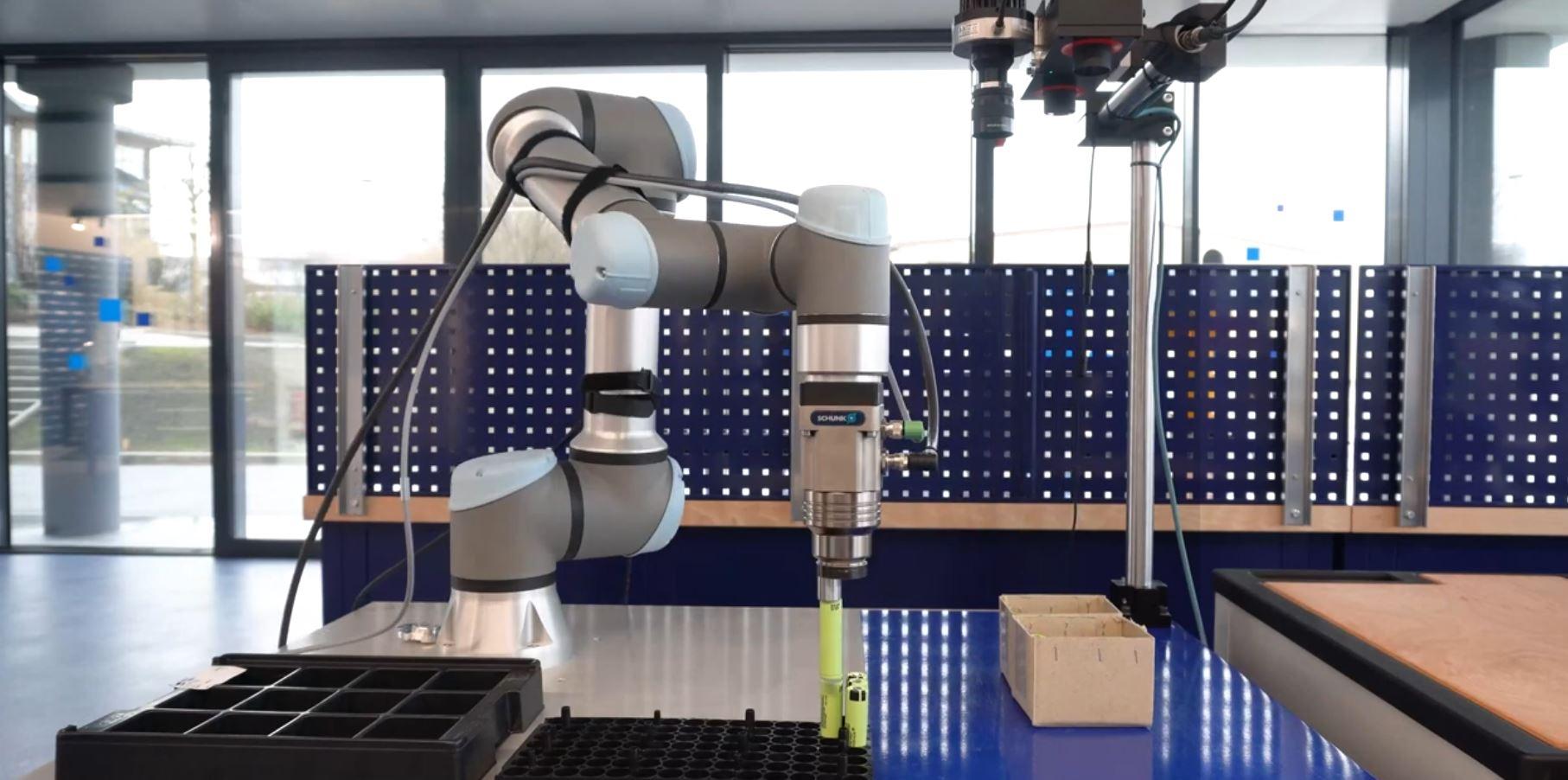

1 / 3Bin picking with a rotary gripper

Test before Invest

Hardware Price:

Feature

lubricant-free

ROI

3

months

Saving potential

High

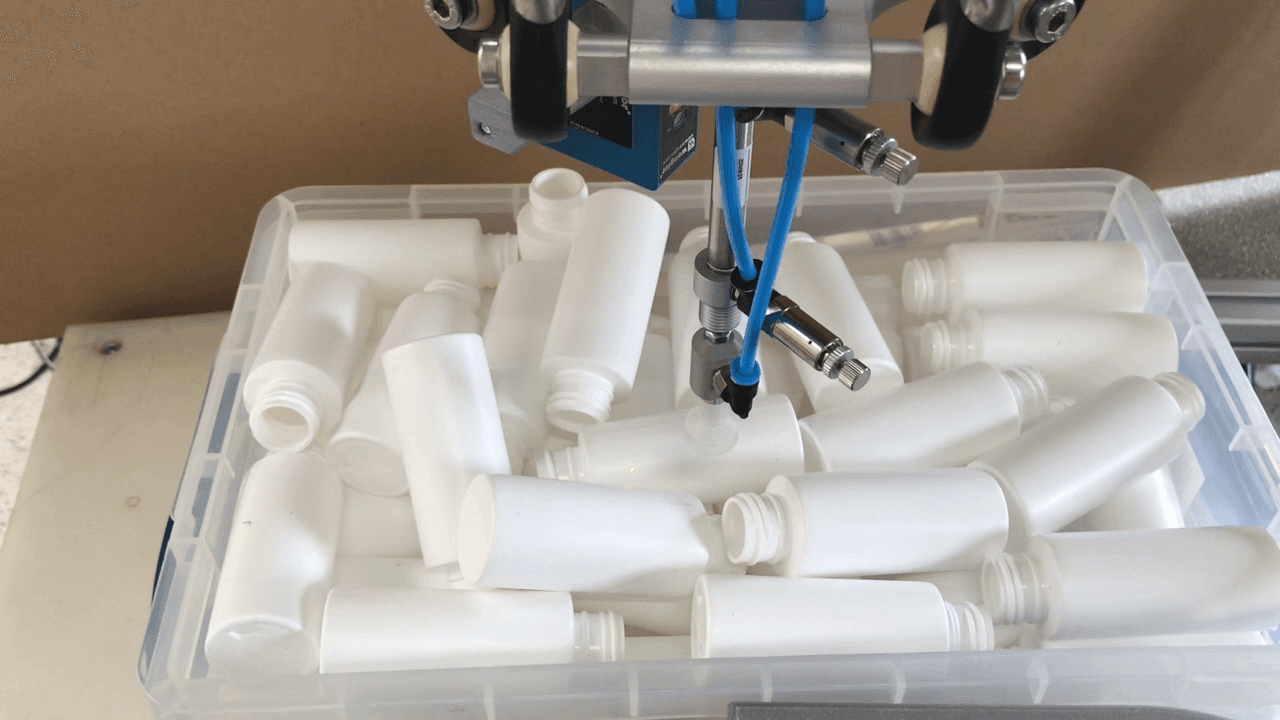

In this particular customer test, which focuses on the handling of metal components, these components are placed in an unsorted state on a device called a Varioshaker. The Varioshaker is a specially designed device capable of shaking and moving the metal components to alter their positions.

Before the test begins, a camera equipped with advanced image recognition capabilities is trained on the contours of the metal components. This allows the camera to recognize and identify the specific shapes and patterns of the various components.

After the Varioshaker has shaken the metal components, the camera captures the positions of the correctly positioned parts. It records the exact coordinates of these parts and transmits this information to the robot’s control system. This process enables the robot to know exactly where the correctly positioned parts are located.

The robot, equipped with a precise and efficient gripping device, then picks up the metal components. It is capable of picking up the components safely and without damage, which is crucial for the subsequent process.

Finally, the robot brings the picked-up metal components into the subsequent process. This could be, for example, an assembly line or another type of manufacturing process. In this process, the metal components are further processed or integrated into larger assemblies. This entire sequence ensures that the metal components are handled efficiently and precisely, leading to improved product quality and productivity.

4 Components