1 / 3

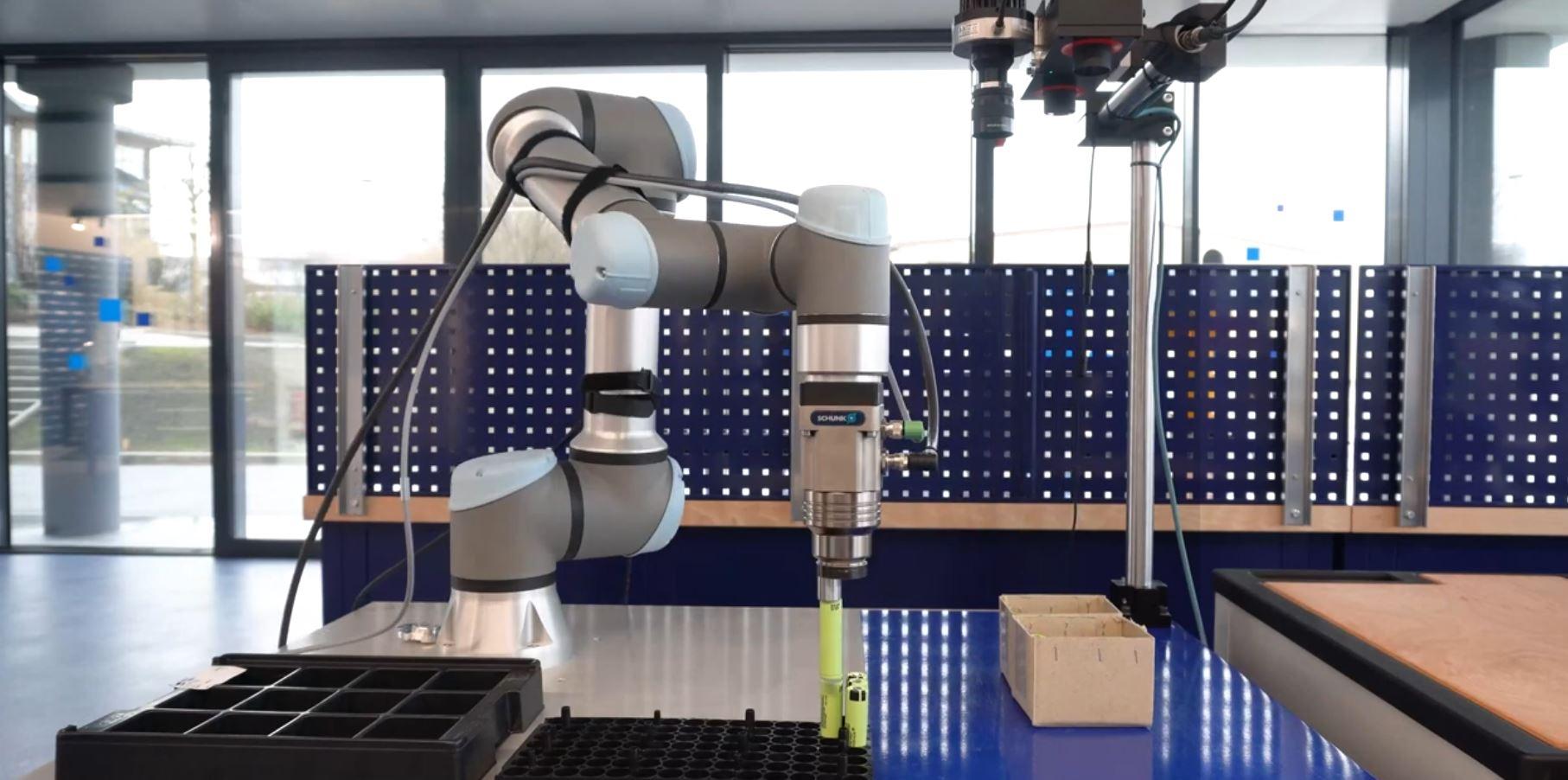

1 / 3Universal Robots application example - TruArc Weld 1000 welding cell

Hardware Price:

DOF

6

Repeatability

0.03

mm

Max. range

850

mm

Flexible Welding Automation: Tackling Labor Shortages with Precision

B&S Blech mit System GmbH, a leader in sheet metal processing, specializes in manufacturing both simple and complex parts. To address the challenges of skilled labor shortages and optimize series production, the company introduced the TruArc Weld 1000 robotic welding cell by Trumpf, in partnership with Universal Robots. This system combines a collaborative UR10e arm with a Fronius welding source, seamlessly controlled by intuitive Trumpf software, delivering precision welding for workpieces up to 2 meters.

What is the Application?

The robotic welding cell automates series production welding, relieving skilled welders from repetitive processes while maintaining consistent quality standards.

What are the Advantages of the Solution?

Time Savings: Cuts welding time by 48% for a batch of 50 pieces.

Ease of Use: User-friendly controls tailored to the robot’s kinematics simplify operation.

Increased Productivity: Frees skilled welders to focus on complex, high-value tasks.

What are the Advantages of the Robot?

The UR10e collaborative robot offers robust capabilities for welding automation:

High Precision: Ensures consistently accurate seam welding.

Collaborative Design: Safely operates alongside human workers in shared spaces.

Scalable Efficiency: Adapts to varying batch sizes and production demands.

Revolutionizing Welding for Medium-Sized Enterprises

The TruArc Weld 1000 robotic cell demonstrates how automation is an effective solution to labor shortages in sheet metal processing. By minimizing time, reducing repetitive work, and enabling precise results, this system provides medium-sized companies with an efficient, scalable approach to modernizing their production workflows.

1 Component