1 / 3

1 / 3Lid handling for the food industry

Test before Invest

Hardware Price:

Repeatability

1

mm

DOF

3

Max. reach

660

mm

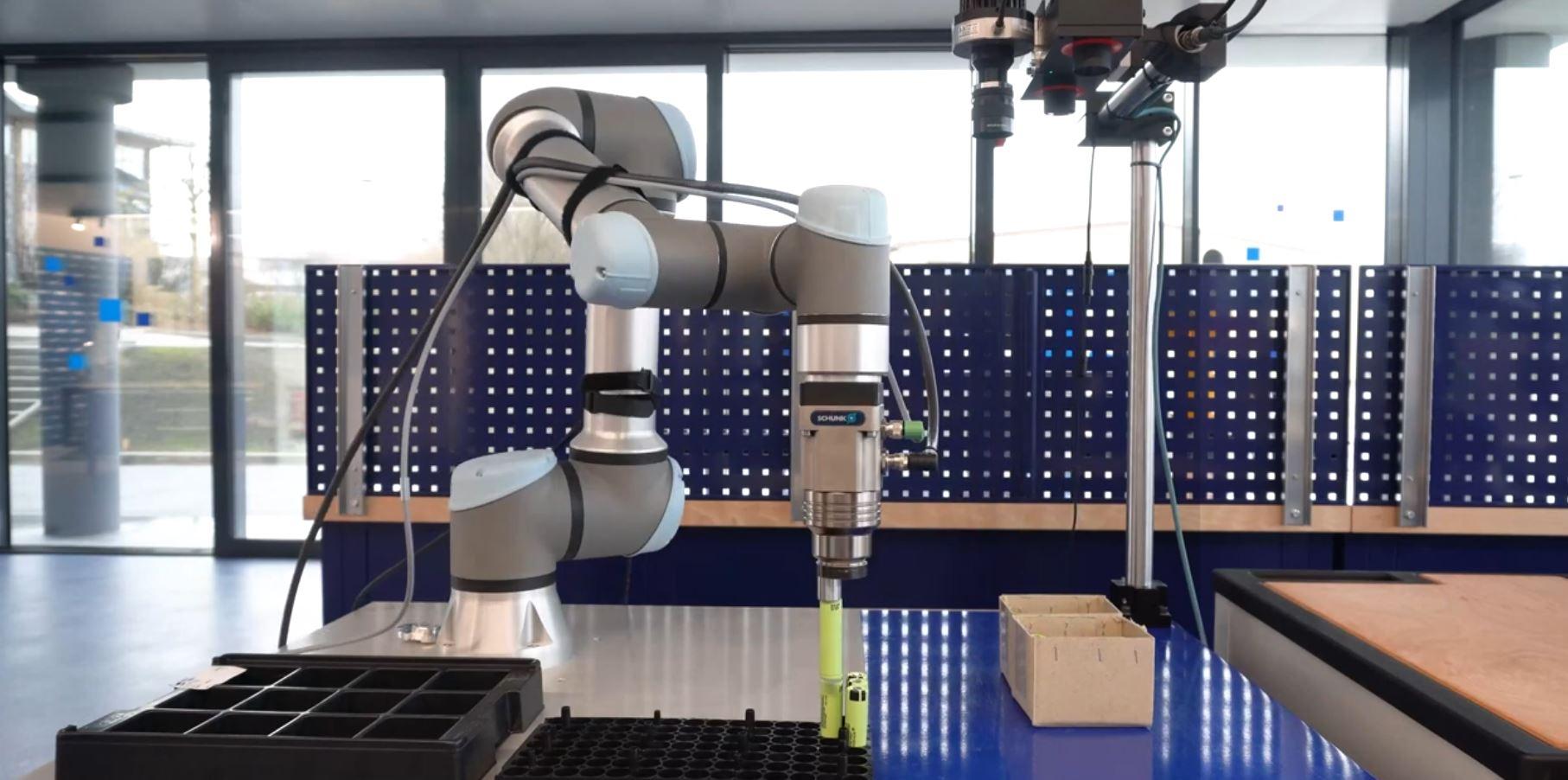

Precise Lid Stacking with igus ReBeL Cobot and Schmalz Suction Cup

This application, showcased in the Customer Testing Area at igus Inc., highlights the precision of the igus ReBeL cobot in a real-world customer test. Equipped with a Schmalz suction cup, the collaborative robot stacks bucket lids used in the food industry. The cobot uses suction to securely pick up the lids and precisely stack them, demonstrating its ability to handle repetitive tasks with accuracy and consistency—critical for food industry applications.

What is the Application?

The system automates lid stacking for food industry buckets, ensuring efficient handling and repeatability in tasks that require precision.

What are the Advantages of the Solution?

High Precision: Guarantees consistent stacking for uniform results.

Operational Efficiency: Reduces manual intervention with seamless automation.

Food Industry Compliance: Meets hygiene and safety standards required for sensitive materials.

What are the Advantages of the Robot?

The igus ReBeL cobot offers reliability and adaptability in industrial workflows:

Collaborative Design: Safely operates alongside human workers.

Smooth Handling: Works reliably with the Schmalz suction cup for secure gripping.

Compact Footprint: Fits easily in restricted production areas.

Enhancing Food Industry Efficiency with ReBeL Automation

This demonstration of the igus ReBeL cobot showcases its ability to automate precise and repetitive tasks like lid stacking. By combining smooth suction handling and collaborative features, it provides food industry manufacturers with an efficient, reliable, and scalable solution for improving productivity in sensitive applications.

3 Components