1 / 3

1 / 3Conveyor belt picking with igus SCARA

Test Before Invest

Hardware Price:

Dynamics with 0.5 kg

20

picks/min

DOF

4

Max Payload

2

kg

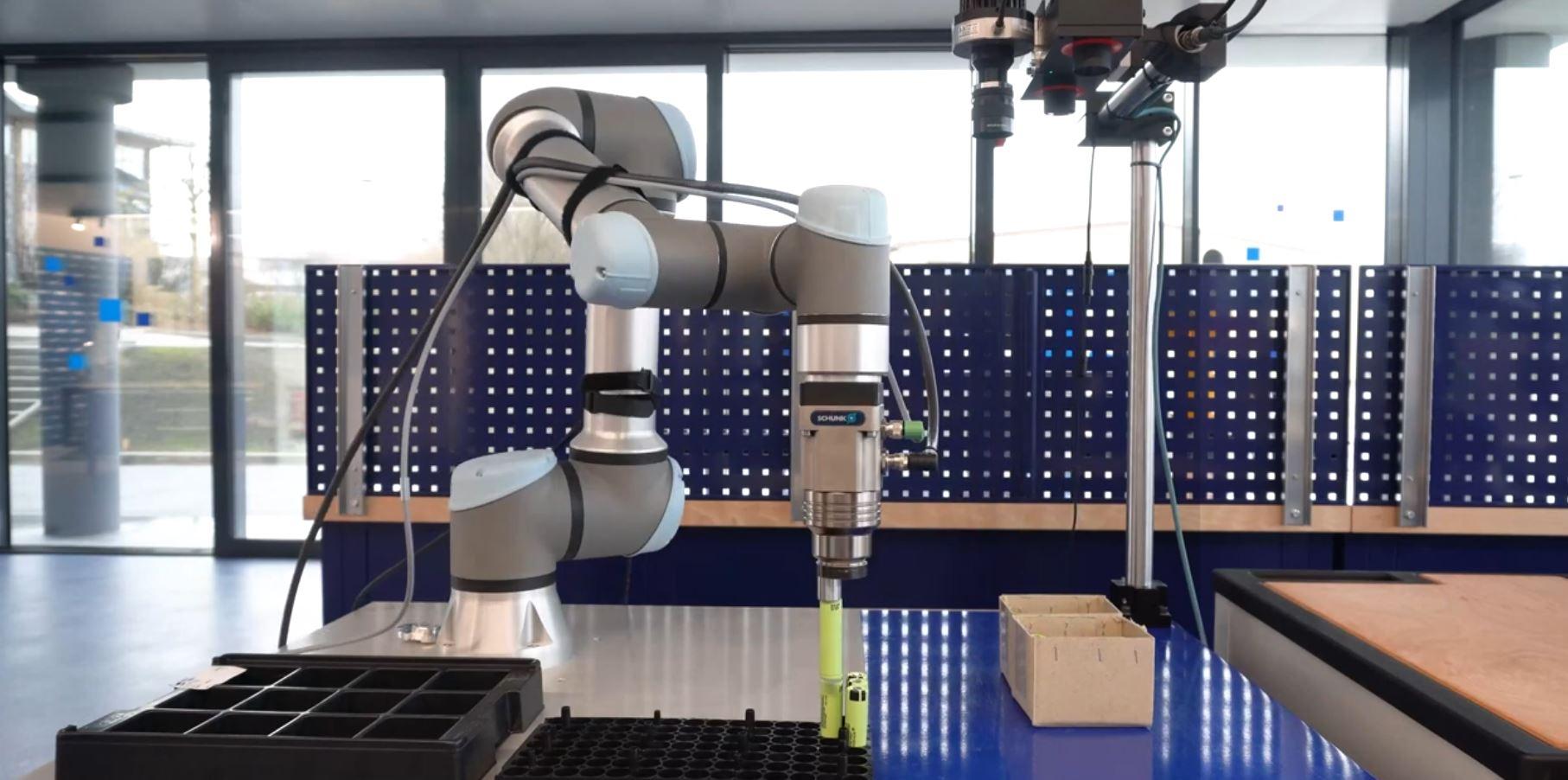

igus SCARA Robot with Schunk Gripper: Efficient Pick-and-Place Solution

Automating pick-and-place tasks is essential in manufacturing and packaging workflows. In this customer test, the igus SCARA robot, equipped with a high-precision Schunk gripper, showcases its ability to handle various items moving on a conveyor belt. With rapid and accurate movements, the system exemplifies smooth operation and high repeatability, making it ideal for applications requiring precision and reliability.

What is the Application?

The system automates pick-and-place operations, efficiently picking items from a moving conveyor belt and placing them into predetermined positions with consistent accuracy.

What are the Advantages of the Solution?

Improved Productivity: Speeds up workflows by automating repetitive tasks.

High Adaptability: Handles items of varying shapes and surfaces seamlessly.

Easy Integration: Fits into existing production lines without complex adjustments.

What are the Advantages of the Robot?

The igus SCARA robot and Schunk gripper deliver robust performance:

Precise Handling: Ensures secure grip and accurate placement of components.

Rapid Movements: Maximizes efficiency in fast-paced environments.

Reliability: Repeatable motions enhance quality and consistency.

Enhancing Processes with Automated Pick-and-Place

This igus SCARA robot system highlights the value of automation in production lines. With its precision, speed, and easy adaptability, it optimizes workflows, reduces manual errors, and supports higher throughput—perfect for businesses seeking scalable and efficient manufacturing solutions.

4 Components